Instruments for industrial process control

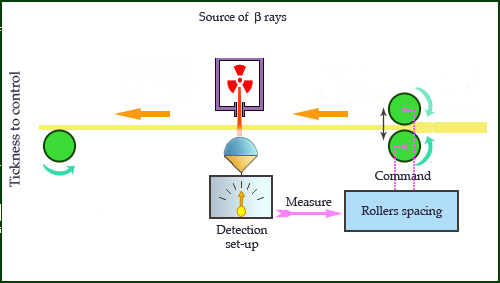

Control principle of paper thickness

The spacing of the rollers that determines the thickness of the sheet of paper is controlled by a device that takes into account the paper thickness measured from the attenuation of the beta electron beam of a radioactive source. The use of beta radiation is adapted to the obstacle formed by the paper. Gamma rays would cross it also easily.

© IN2P3

In order to be peforming and efficient; modern industry has set the bar very high for the instruments that continuously monitor the steps of an industrial process. This involves measuring and, if it is necessary, quickly adjusting the quality and specifications of products during their manufacturing process. Many process control are using radioactive gauges.

For example, checks are performed on production lines, to continuously monitor the level of liquids in drums, the density of materials in containers, the thickness of plates, sheets, coatings, or the quantities and compositions of raw materials on conveyor belts.

Due to the penetration power of radiations such as gamma or neutron, direct contact of the object to be tested with the source or the detection device is not necessary. This allows non-destructive measurements in real time, while the matters to be followed undergo the steps of an industrial process.

The principle of operation of these various gauges is the same: the attenuation of the signal received from the emitted signal allows assessing the magnitude sought.

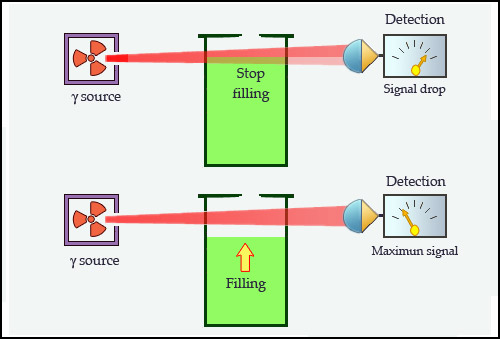

Principle of a filling control

Measuring the level when filling a can : a gamma ray beam passes through the container filling before being received at a detector-situated on the opposite side. When the liquid intercepts the beam of gamma rays, the signal seen by the detector drops sharply. This drop can trigger automatically the end of the filling action. The radionuclides used depend on the characteristics of the container and its liquid content.

© IN2P3

In the case of a level gauge, the source is placed on one side of a container to fill and the sensor against the opposite wall. When the liquid rises to intercept the line between the two instruments, the amount of radiation received by the detector drops sharply. This technique is used for example to fill cans of soda or lighters. The attenuation of the signal on the detector can determine the level of filling of the container and can cause automatically shutdown, further filling, or an alarm.

It uses the absorption of gamma and the same principle to measure the density and mass of materials present within a container. Using feeler gauges based on radioisotopes is widespread in industries producing plates of material. Without radioisotopes, it is unlikely that automation could have developed in these industries. The modern steel factories use such gauges to measure the thickness of the metal plates coming out of rolling mills at each stage of production.

It is also the case for papermaking, including with the accurate measurement of the wet pulp in the early stages of production. For the control of the weights of the paper, one uses beta rays because the thin sheets is too transparent to absorb gamma rays. A beta electron beam passes through the paper and is received on a detector located vis-à-vis. The attenuation of the signal on that detector ameasures the paper density and thus its weight.

According to the Nuclear Safety Authority, the radionuclides most commonly used for these applications are krypton-85, cesium 137, americium-241, cobalt-60 and prometheum 147. The range of the sources activities are between a few kilobecquerels (kBq) and a few gigabecquerel (GBq).

Other articles on the subject « Applications of Radioactivity »

Inspection and controls

A tool for testing and tune-ups The penetrating property of radiations is commonly used to check [...]

Material Developmnent

Improvements in the quality of industrial products Every day we make use of products that have be[...]

Non Destructive Testing

Control of industrial processes and materials Tracers and radioactive sources are frequently used[...]

Food processing

Eradicate bacteria, fungi and pests with radiation … Gamma rays are used industrially to en[...]

Food Preservation

Conservation and preservation of food The effects of radiation on the cells of living or vegetabl[...]

Conservation Effects

A conservation process without additives, non radioactive The biological effects of strong doses [...]

Medfly Eradication

The curse of the medfly and its eradication The Mediterranean flies or Medflies are a dreadful cu[...]

Disinfecting Effects

Getting rid of parasites and germs….. The radiobiological action of radiation leads to damage to [...]

Sources in Industry

A wide variety of applications Most radioelements in radioactive sources are extracted from small[...]

Various Applications

Because of the fears it inspires, radioactivity is considered in the collective unconscious as ho[...]