Improvements in the quality of industrial products

Every day we make use of products that have been exposed to radiation in their manufacture. These items themselves are entirely non-radioactive and, in fact, have had their quality improved thanks to their exposure to radiations.

In addition to being used in controls or to make improvements to the production process, radiation can be used to modify the physical structure of the products, conferring altered properties with a range of new applications.

Under certain conditions, radiations can lead to chemical reactions (the release of free radicals) which help make substances lighter and more resistant: a highly effective technique in the manufacture of insulators, electric cables and prosthetics.

An unexpected application…:

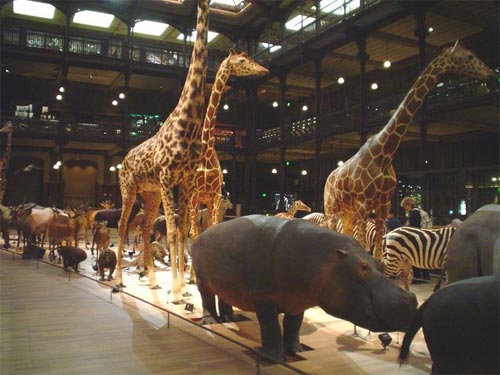

Radioactivity, woodcutting industry and the evolution of species ! The connection may seem obscure, but museum curators have good cause to worry about their fragile wood floors. Trodden by thousands of visitors a year, the floor of the Great Hall at the Natural History Museum in Paris has been impregnated with resin and exposed to gamma rays: thus making it as hard as stone and considerably more attractive.

© Paris-en-photos

These techniques have allowed to improve the molecular structures of a wide variety of commonly-used products. Certain plastics can be induced to retract when heated: thermoretractable materials are frequently used in the packaging industry. Additional layers added to insulate cables or electrical wires can thus be made resistant both to heat and chemical reactions. Plastics altered in this way are heavily used in the car and aerospace industries, as well as in a range of electrical household appliances.

Card game amateurs welcome the plastic lamination that covers their cards which is highly resistant to physical damages: irradiation have contributed in achieving this goal …

Some cooking tools have benefited from an irradiation treatment: the non-stick coating used in certain frying pans is made by irradiating small pieces of Teflon. The ‘Tefal’ range of frying pans in particular relies on the irradiation of microscopic Teflon shavings for its characteristic anti-adhesive properties.

In the tyre industry, several manufacturers employ irradiation to vulcanise the rubber they use; a procedure which is far more effective than the conventional sulphur-based techniques usually employed.

On an entirely different note, one effect of irradiation is the changing of some molecular structures which allows for greater absorption of liquids. This property has been used to great effect in making super-absorbent baby diapers, to the relief of parents around the world.

It is also possible to impregnate wood with a resin that hardens under exposure to radioactivity and then, after the unwanted air bubbles have been removed, to harden the resin. Thanks to the sharing of technologies, this procedure, which was once used exclusively in the restoration of works of art, is now used in the strengthening of wood floors. Harder, denser woods can thus be obtained which combine wood and plastic, all the while maintaining the aesthetic appeal.

Other articles on the subject « Applications of Radioactivity »

Inspection and controls

A tool for testing and tune-ups The penetrating property of radiations is commonly used to check [...]

Non Destructive Testing

Control of industrial processes and materials Tracers and radioactive sources are frequently used[...]

Food processing

Eradicate bacteria, fungi and pests with radiation … Gamma rays are used industrially to en[...]

Food Preservation

Conservation and preservation of food The effects of radiation on the cells of living or vegetabl[...]

Conservation Effects

A conservation process without additives, non radioactive The biological effects of strong doses [...]

Medfly Eradication

The curse of the medfly and its eradication The Mediterranean flies or Medflies are a dreadful cu[...]

Disinfecting Effects

Getting rid of parasites and germs….. The radiobiological action of radiation leads to damage to [...]

Radioactive Gauges

Instruments for industrial process control In order to be peforming and efficient; modern industr[...]

Sources in Industry

A wide variety of applications Most radioelements in radioactive sources are extracted from small[...]

Various Applications

Because of the fears it inspires, radioactivity is considered in the collective unconscious as ho[...]