Reprocessing highly radioactive waste in the Hague

Uranium reprocessing techniques were developed during the Second World War and ensuing cold war, as a means of extracting plutonium for atomic bombs. These ultra-sensitive processes remained secret for many years, and reprocessing remains a key focus for non-proliferation issues. Their application to civilian nuclear power is currently subject to very strict regulations and inspections, relating in particular to the nature and quantity of substances reprocessed. Operations at a plant such as the facility in the Hague are constantly monitored by cameras installed by international agencies such as IAEA and EURATOM.

The La Hague reprocessing plant

The AREVA plant in the La Hague near Cherbourg is the world’s largest industrial fuel reprocessing facility. Other plants also exist, in Sellafield in England, in Russia and in Japan. Alongside the reprocessing facilities, the La Hague plant processes spent fuel from power plants in France and several other, mainly European countries.

© AREVA

Spent fuel from civilian reactors contains plutonium unsuitable for use in atomic bomb manufacturing processes. Should such highly radioactive materials be treated as waste or not? The question is a matter of intense debate. Some countries have chosen the option of reprocessing this fuel, including Japan and France, which is home to the world’s largest plant, located in La Hague.

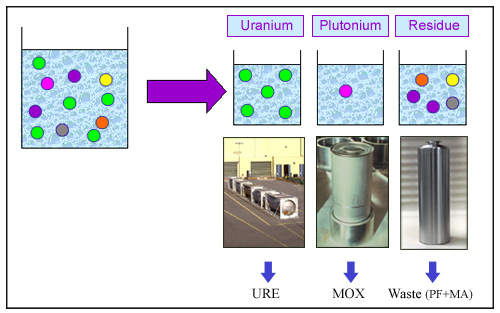

Industrialised reprocessing consists in separating out the uranium and plutonium from waste made up of products that largely have no value from an energy recovery perspective. Note that spent fuel contains 95.5% uranium and 1% plutonium, with the remaining 3.5% consisting of fission products and minor actinides

and minor actinides .

.

Separating waste from recoverable materials

The purpose of chemical reprocessing operations is to separate the atoms found in irradiated fuel pellets into three fractions: recycled enriched uranium (URE), which can be recycled as it still contains 1% of fissile isotope 235; plutonium, of which 70% of the nuclei are fissile and can produce energy; residual fission products and minor actinides, treated as waste.

© IN2P3/Ires

There is little benefit in reprocessing waste in order to recover plutonium if nuclear power is abandoned in the near future. Conversely, if nuclear power is used to combat climate change and address booming energy demand in countries such as China and India, reprocessing spent fuel would appear to be essential, albeit not necessarily using the same process as today. Almost all of the planned fourth-generation reactor concepts that aim to produce cleaner, less resource-intensive nuclear power will recycle and hence reprocess their fuel.

Currently, the plutonium in civilian reactors – which has a composition unsuitable for use in nuclear weapons – is included in reactor fuel and helps to produce energy.

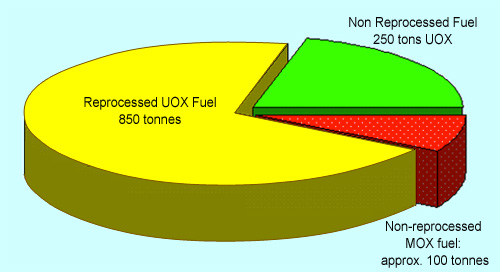

Repartition of spent fuel reprocessed or not reprocessed in France

Approximately 1,200 tonnes of spent fuel exits French nuclear power plants each year. Approximately 850 tonnes of this is reprocessed. EDF does not reprocess all irradiated fuel, as there are only 20 reactors capable of recycling plutonium but 28 would be necessary. Each year, 350 tonnes are stored in pools, of which 100 tonnes of MOX. EDF has stated that it intends to ultimately reprocess this stored fuel.

© IN2P3

Reprocessing greatly reduces waste volumes and enables safe packaging: Almost all the radioactivity is concentrated in the residues, which represent only 3 to 5% of the fuel mass; these residues are then embedded in glass, which very effectively immobilises radioactivity.

is concentrated in the residues, which represent only 3 to 5% of the fuel mass; these residues are then embedded in glass, which very effectively immobilises radioactivity.

Current industrial reprocessing is one stage in a process. Research is underway to also separate the minor actinides that currently remain in the vitrified waste. This would result in lighter glass, which would return to background radioactivity levels much more rapidly. Furthermore, the aforementioned fourth-generation reactors would be able to recycle and efficiently burn plutonium and certain problematic radioelements such as minor actinides.

such as minor actinides.

Articles on the subject « Fuel reprocessing »

Reprocessing operations

A multi-year sequence of operations Reception of the spent fuel assemblies is the first stage of [...]

Purex process

Purex – Industrialised spent fuel processing Fuel is processed at the LaHague facility using a hy[...]

Reprocessing performance

Past achievements and future improvements When the plant in La Hague was commissioned in 1976, it[...]

Effluents and releases

Low and well-controlled environmental releases A small portion of the radioactive waste from nucl[...]

La Hague – Safety

Safety issues different to those faced by reactors The events of 11 September 2001 raised the spe[...]