Dosimetry by « Optically stimulated luminescence »

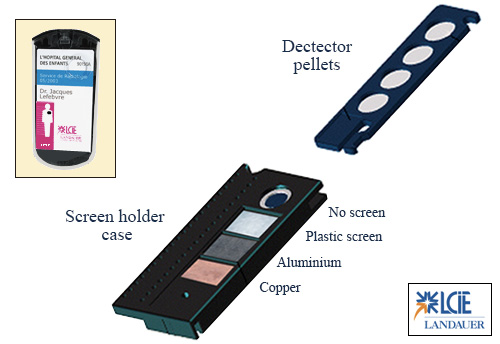

Detection components of an OSL dosimeter

This LCIE Landauer InLight dosimeter comprises four carbon-doped aluminium oxide detector elements of 5 mm diameter which are inserted into a plate having 4 holes. This plate fits into a screen holder equiped on front and back with 4 filters – no screen, plastic, aluminum and copper – positioned in front of each pellets. Thanks to this system, the detectors are able to measure and differentiate X, gamma and beta radiations, independantly of the dosimeter orientation.

© LCIE Landauer

The active element of an OSL detector is a thin pellet cut in a ribbon consisting of a carbon-doped aluminum oxide powder. This powder comes from a crystal obtained by mixing at high temperature pure aluminum oxide and carbon. This powder is then coated with a binder between two strips of polyester film, the assembly thus forming a ribbon.

Doping means that carbon atoms have taken the place of aluminum atoms in the crystal structure. These atoms have the ability to trap electrons from the crystal.

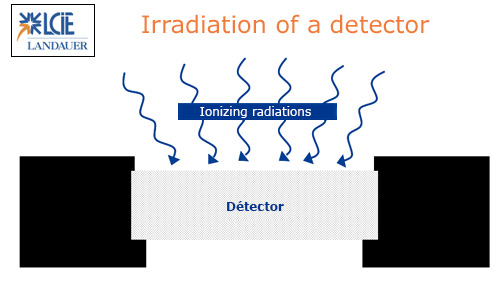

Dosimeter exposition

During interactions with ionizing radiation, electrons in the crystal structure of an OSL detector are trapped by carbon atoms introduced as impurities. These trapped electrons have higher energy than non-trapped electrons. As the irradiation progresses, the number of trapped electrons increases. Latent energy is thus stored in the detector. This number of electrons and the latent energy stored are in proportion to the dose received.

© LCIE Landauer

But to be trapped, these electrons need extra energy. This supplement is provided by the ionizing radiation that passes through the crystal and whose effect is to increase the number of electrons trapped. This number and the energy thus stored are in proportion to the dose received.

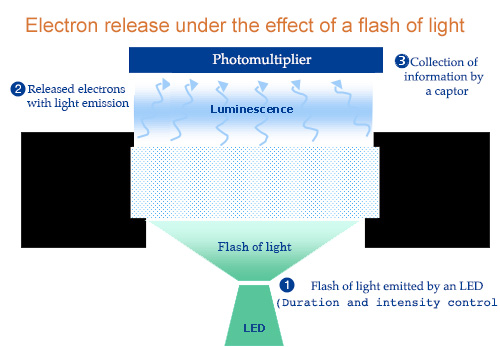

The measurement of the dose consists in measuring the stored energy. The reading is carried out by sending on the crystalline powder, which is transparent, a brief flash of light. Because of the light excitation, electrons trapped by the carbon atoms are released and restore the energy they stored in the form of a light pulse, a luminescence. It is this pulse of light, the intensity of which is proportional to the number of electrons trapped in the dose, which is measured.

The luminescence is triggered by a light flash – laser, light emitting diode – while it is caused by heating in the case of thermoluminescence. The intensity and duration of the stimulation source are easily controllable. As a result, only a small proportion (0.5%) of the charges retained in the sensitive material is released. A very large part of the information is stored in the sensor. Unlike the TLD where the traps are completely emptied, optical stimulation allows to read again the dosimeter.

Reading an OSL dosimeter

To measure the dose, it is necessary to measure the energy stored during the irradiation. To do this, the crystal is briefly illuminated by a diode emitting light (LED). This luminous flash (whose intensity and duration are controlled) releases a fraction of the electrons trapped by the carbon impurities. These electrons release their energy excess in the form of light. This emission of light, proportional to the number of electrons trapped, and therefore to the dose, is measured by a photomultiplier.

© LCIE Landauer

Utilisation and applications

OSL dosimeters are part of the passive dosimetry techniques recognized by the French regulations with radiophotoluminescent (RPL), thermoluminescent (TLD) dosimeters and photographic films. This technology, which appeared in the 1990s, is now widespread with more than 1,300,000 people wearing these dosimeters worldwide each month.

OSL dosimeters have qualities that explain why they are widely used: non-destructive reading; an extensive measuring range from 0.01 mSv to 10 Sv; better sensitivity to all energies than photographic film and TLD ; insensitivity to heat and humidity, as well as to neutron radiation.

Finally, with reading resources available on site, these dosimeters allow environmental controls in industry, laboratory or hospital since they can be read as many times as necessary. For example, they make it possible to control doses of radiation delivered during medical procedures (radiotherapy, scanners).

Other articles on the subject « Dosimetry »

Passive Dosimeters

Portable dosimeters for monitoring of exposed people Dosimeters called passive are dosimeters tha[...]

RPL Dosimeters

Sensitive, robust and widely used dosimeters These passive dosimeters use radiophotoluminescence [...]

TLD Dosimeters

Exploit thermoluminescence for dosimetry The energy provided by ionizing radiation may cause defe[...]

Active Dosimeters

For real-time monitoring of workers exposed to radiation Active dosimeters are in fact ele[...]