A separation process economical in energy, but proliferating

The principle of centrifuges has long been known. On yesteryear farms, churns already separated whey from cream to make butter. Today fast centrifuges are used to separate all kinds of components under the effect of centrifugal force. This centrifugal force is proportional to the particle mass, the square of its velocity and the inverse of the radius of rotation. The most massive particles inside a centrifuge feel the strongest force and tend to migrate more towards the wall.

In the case of centrifuges used for uranium enrichment, the mass difference between the two types of atoms to be separated is barely 1%. One must use very high speeds reaching hundreds of meters per second at the wall. The outer rotor wall of the centrifuge is subjected to accelerations of the order of tens or even hundreds of thousands of times the acceleration due to gravity (*) . The centrifuge should be made of extremely resistant materials and avoid any imbalance or any structural defect to avoid any risk of seeing the centrifuge shattered.

. The centrifuge should be made of extremely resistant materials and avoid any imbalance or any structural defect to avoid any risk of seeing the centrifuge shattered.

Progress achieved in material strength, thanks to the use of carbon fiber in the late 1980s, has allowed the development of ultracentrigugation. This technique, which has several decades of experience, is now well developed. Consuming much less electricity and requiring less heavy equipment, ulltracentrigugation replaces gaseous diffusion.

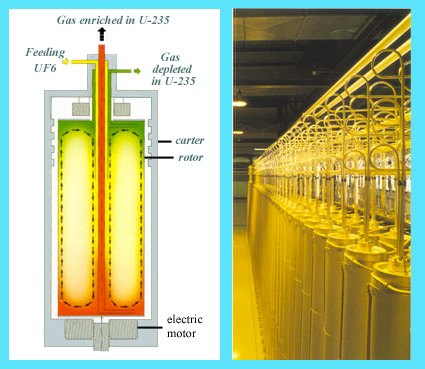

The process involves feeding uranium hexafluoride, made gaseous by heating, in an ultracentrifuge, spinning at high speed. The heavier uranium atoms (U-238) migrate to the periphery of the machine while the lightest (U-235) migrate preferentially towards its axis. Uranium atoms near and not near the axis are pumped separately and sent to another centrifuge.

Cascade of uranium centrifuges

Uranium gas is fed into cascades of thousands of centrifuges with a rotor 1 to 2 m high and 15-20 cm diameter. When the rotors rotate at very high speeds, molecules with uranium-238 atoms tend to move more near the outside cylinder wall than those with uranium-235 around the cylinder axis. For an efficient separation, centrifuges should turn 50 000-70 000 revolutions per minute, a speed of the outside cylinder wall of 400-500 m per second. The slightly enriched fraction centrifuge will feed the next centrifuge, while the depleted fraction returns to the previous one.

© URENCO/IN2P3

At the level of one single centrifuge, the modification of the proportions of uranium 238 and 235 are marginal. To achieve a significant enrichment, gas must pass through housands of centrifuges arranged in cascades. The process is modular. Production units can be quite small and energy needs are reasonable, 50 times lower than for gaseous diffusion.

If centrifugation can supply enriched nuclear fuel for civilian reactors, it can also provide highly enriched uranium suitable for atomic bomb. The technique is proliferating. For uranium enriched to 90% that goes into the making of bombs, one just needs to continue the enrichment well beyond the 4% requested for reactors fuels.

It has long been assumed that the centrifuge was within the high technology and that only the most advanced industrial countries were able to manufacture the required critical components. The evolution of the global economy has altered this vision. Since 1990, companies have relocated their operations to advanced Asian countries where the manpower has gradually acquired expertise in the processing of new materials, manufacturing very delicate equipment and compliance with strict specifications. For instance, when the centrifuges trafficking organized by the Pakistani scientist Abdul Khader Khan was unmasked in 2002, it appeared that parts of centrifuges had been manufactured in Malaysia.

Basically, centrifuges can be used to enrich uranium for reactors – which is in principle legitimate – or to fabricate weapon-grade uranium. Because of this duality, it is difficult to distinguish facilities aimed at civilian purposes (which also include the extraction and conversion of uranium) from those intended for nuclear weapons. These enrichment facilities are under IAEA inspections, which are able to detect the presence of such highly enriched uranium. But the inspections have only access – in the countries signatories of the Nuclear Non-proliferation Treaty – to declared facilities. For example Iran undergoes for such inspections but the U.S. suspects them developing a secret program through the know-how acquired.

ALSO : Gaseous diffusion

Other articles on the subject « Nuclear Fuel »

Nuclear Fuel Cycle

The front-end and the back-end of the cycle… The nuclear fuel cycle includes all nuclear op[...]

Cycle Front End

From the extraction of uranium to the fuel fabrication The front-end of the nuclear cycle is the [...]

Isotopic Separation

The access key to the fuel of modern nuclear power plants … and to atomic weapons The uranium fue[...]

Gaseous Diffusion

The first enrichment process, a large consumer of electricity The gaseous diffusion process was t[...]

PWR fuel assemblies

Fuel assemblies in the core of PWR Reactors The core of a pressurized water reactor (PWR) is cont[...]

Reactor fuel layout

Fuel assemblies in the core of nuclear reactors The nuclear fuel assemblies, that vary from one r[...]

Plutonium Use

A fissile element produced in nuclear reactors In February 1941 the American physicist Glenn Seab[...]

Pu : Fuel, bomb or Waste ?

Plutonium dark and bright sides … Sensitive material, like the roman god Janus, plutonium h[...]

MOX fuels

Introducing plutonium in nuclear fuels For energy production, plutonum is gold ! One gram of plut[...]

Thorium Fuels

Uranium 233: a fissile nucleus made from thorium Thorium is more abundant than uranium in the Ear[...]