The first enrichment process, a large consumer of electricity

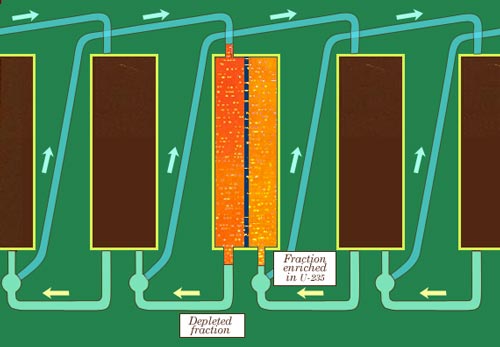

Principle of gaseous diffusion

Uranium is injected in the form of hexafluoride of gaseous uranium. Hexafluoride molecules must pass through very fine membranes pierced by billion pores per cm2. The lighter molecules containing the isotope-235 cross a little faster these barriers. At the end of 1400 barriers of the Georges-Besse plant; the enrichment level of about 4%, required for reactor nuclear fuels, is achieved.

© AREVA

The gaseous diffusion process was the first process of uranium isotopic enrichment to reach the industrial scale. The Americans used it during the Manhattan Project during World War II to produce the first atomic bomb.

Uranium is injected in the form of a gaseous compound, uranium hexafluoride. Hexafluoride molecules have to go through very fine membranes pierced by billion pores per cm2. The lighter molecules containing the isotope-235 cross a little faster these barriers. After a large number of barriers, one get the desired fuel enrichment level.

In France, the gaseous diffusion of uranium hexafluoride was implemented as soon as 1958 at Pierrelatte to obtain the highly enriched uranium needed for the National Defense. Then, countries of Western Europe joined forces in the 1960s to master this technology. Since 1979, the Georges Besse EURODIF plant ensures a production of enriched uranium for civilian purposes.

This very large facility is located on the site of the Tricastin nuclear power plant in the Rhone Valley. It is able to supply 90 reactors of 1 Gigawatt electric power. It provides about 25% of global demands for enriched uranium to fuel reactors. Its clients include EDF and more than 30 companies of electricity.

The drawback of gaseous diffusion is to consume a lot of energy. Gaseous diffusion requires 2500 kWh per « separation work unit » against 50 kWh for the ultracentrifugation process. The Georges Besse plant requires 3 to 4 units of the Tricastin nuclear plant to operate at maximum of its production capacities. If the exploitation remains profitable, it is because the plant investment has been amply paid off.

As long as gaseous diffusion was the only technique available, the isotope separation was reserved to major industrial nations. The electric power required put it out of reach of middle size nations. Having no access to enrichment technology, they could not use it to make the highly enriched uranium of bombs.

Diffusers at the Georges Besse plant

To achieve a level of 3 to 5% of uranium-235, the gaseous uranium hexafluoride should go through a series of porous barriers constituting the « diffusion cascade. » The cascade of the Georges Besse plant is made of a sequence of 1400 stages, each stage including a diffuser, a compressor and a heat exchanger

© PHILIPPE LESAGE / AREVA

For cost reasons, the United States and France plan to replace their ageing enrichment plants by ultracentrifugation. The exploitation of the Georges Besse plant, extended beyond the originally planned 20 years, will not continue beyond 2010-2015. To continue with the gaseous diffusion technology would be prohibitive. For this reason, the company AREVA, first worldwide producer of enriched uranium, has chosen the centrifugal process and signed an agreement with its European rival, consortium Urenco, to acquire this technology.

On June 7, 2012, after 33 years of operation, the Georges Besse plant located on the Tricastin site has permanently phased out its production. Its successor, the Georges Besse II plant is in production since April 2011. It uses the ultraecntrifugation enrichment technology that consumes 50 times less electric power and significantly reduce the needs of cooling water.

NEXT : Ultracentrifugation

Other articles on the subject « Nuclear Fuel »

Nuclear Fuel Cycle

The front-end and the back-end of the cycle… The nuclear fuel cycle includes all nuclear op[...]

Cycle Front End

From the extraction of uranium to the fuel fabrication The front-end of the nuclear cycle is the [...]

Isotopic Separation

The access key to the fuel of modern nuclear power plants … and to atomic weapons The uranium fue[...]

Ultracentrifugation

A separation process economical in energy, but proliferating The principle of centrifuges has lon[...]

PWR fuel assemblies

Fuel assemblies in the core of PWR Reactors The core of a pressurized water reactor (PWR) is cont[...]

Reactor fuel layout

Fuel assemblies in the core of nuclear reactors The nuclear fuel assemblies, that vary from one r[...]

Plutonium Use

A fissile element produced in nuclear reactors In February 1941 the American physicist Glenn Seab[...]

Pu : Fuel, bomb or Waste ?

Plutonium dark and bright sides … Sensitive material, like the roman god Janus, plutonium h[...]

MOX fuels

Introducing plutonium in nuclear fuels For energy production, plutonum is gold ! One gram of plut[...]

Thorium Fuels

Uranium 233: a fissile nucleus made from thorium Thorium is more abundant than uranium in the Ear[...]