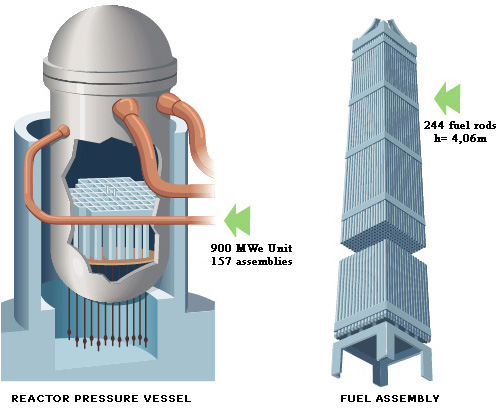

Fuel assemblies in the core of PWR Reactors

The core of a pressurized water reactor (PWR) is contained in a sealed metal vessel. It is composed of fuel rods grouped in assemblies arranged in a mosaic, between which pressurized primary water circulates evacuates heat and moderates neutrons.

Detail of a fuel assembly

Inserted into the reactor core, each fuel assembly is made up of 264 rods approximately 4 m long, each rod being formed from a stack of 272 uranium or plutonium oxide pellets coated with a cladding. zirconium base. Guide tubes are also provided for insertion into the control rod assemblies for controlling the reactor. The different structural parts – grids, end pieces – which ensure the mechanical cohesion of the assembly are also made of materials that absorb little neutrons.

© AREVA

A fuel assembly groups a set of rods held together by support grids. These rods are long tubes that contain stacked fuel pellets. The wall or sheath of these rods and their tips ensure the confinement of radioactive products from the high pressure and high temperature water circulating around.

The pellets are composed of sintered uranium oxides (UO2) or in the case of MOX a mixture of uranium and plutonium oxide. Uranium oxide pellets 1.35 cm high weigh 8.3 grams. A typical pressurized water PWR reactor rod contains 272 pellets from end to end. Its length is 3.85 m. Its height is 4.06 m and a weight of 500 kg. Its fuel weight is approximately 2 kg.

The advantage of the rod configuration is that the newly produced fast neutrons pass through water, which allows them to be slowed down before they reentering the fuel again to produce fissions.

Fuel rods

Fuel rods before assembly. The uranium oxide pellets are stacked inside tubes or sheaths made of a zirconium alloy transparent to neutrons and resistant to water corrosion. The sheaths, which constitute the first sealing barrier, prevent the passage of radioactive elements, some of which are gaseous, into the primary water. Later, these same pencils will provide the first protection for the environment in the case where the irradiated assemblies are stored as waste.

© PHILIPPE LESAGE /AREVA

In total, the core of a reactor unit which provides an electrical power of 0.90 Gigawatt includes 177 assemblies, 46,728 rods and 11,273,856 pellets. It will operate on average 6,600 hours per year. It contains 72 tonnes of heavy metal (mainly uranium) which will remain in the reactor for 3 years and will be renewed each year in thirds of 24 tonnes.

The metal sheaths, coating the fuel rods and immersed in pressurized water at high temperature, are made of zirconium, a rare metal. The use of zirconium developed from 1949 at the instigation of Admiral Rickover as part of the development of onboard reactors for the American nuclear submarines.

It was only later, through the “Atom for Peace” program, that its use was extended to the civil atom. The reasons which led to the choice of zirconium or its alloys are high transparency to neutrons, good mechanical qualities, and good resistance to water corrosion at very high temperatures. Corrosion resistance is improved through alloys, mainly based on tin, called zircaloy.

Visual control

Visual inspection of the fuel rod cap welds, containing the uranium oxide pellets. The sheaths resistant to water corrosion constitute the first sealing barrier, preventing the passage of radioactive elements, some of which are gaseous, into the primary water whose temperature reaches 350°C.

© PHILIPPE LESAGE /AREVA

Later, when the irradiated assemblies are removed from the reactors and stored in pools, it is the sealing of these sheaths which prevents the dispersion of radioactive products and offers a first protective barrier.

See also :

Other articles on the subject « Nuclear Fuel »

Nuclear Fuel Cycle

The front-end and the back-end of the cycle… The nuclear fuel cycle includes all nuclear op[...]

Cycle Front End

From the extraction of uranium to the fuel fabrication The front-end of the nuclear cycle is the [...]

Isotopic Separation

The access key to the fuel of modern nuclear power plants … and to atomic weapons The uranium fue[...]

Ultracentrifugation

A separation process economical in energy, but proliferating The principle of centrifuges has lon[...]

Gaseous Diffusion

The first enrichment process, a large consumer of electricity The gaseous diffusion process was t[...]

Reactor fuel layout

Fuel assemblies in the core of nuclear reactors The nuclear fuel assemblies, that vary from one r[...]

Plutonium Use

A fissile element produced in nuclear reactors In February 1941 the American physicist Glenn Seab[...]

Pu : Fuel, bomb or Waste ?

Plutonium dark and bright sides … Sensitive material, like the roman god Janus, plutonium h[...]

MOX fuels

Introducing plutonium in nuclear fuels For energy production, plutonum is gold ! One gram of plut[...]

Thorium Fuels

Uranium 233: a fissile nucleus made from thorium Thorium is more abundant than uranium in the Ear[...]