Promising reactors … but in a remote future

Molten Salt Reactors are very different in design from other reactors. The fissile material is « diluted » within a liquid : a molten salt. This salt is a lithium fluoride in the majority of projects such as the European MSFR project or a chloride as in the German project DFR. Fissile material and molten salts circulate in the reactor core and the cooling system. The circulation of the salts brews permanently the fuels and the radioactive materials present in the whole set.

1968 – Molten Salt Reactor Experiment

This low-power experimental reactor allowed from 1964 to 1969 first studies on molten salt reactors at the great American OakRidge laboratory. In 1968, a last experiment was even carried out with a fuel containing uranium-233 as fissile material. The photograph shows the Nobel Prize winner Glenn Seaborg, president of the Atomic Energy Commission, at the control panel for the start of the experiment.

© MSRE – Oakridge

The concept was studied with convincing results at the famous American OakRidge laboratory during the 1960s. Under the leadership of Alvin Weinberg, a pioneer in reactor science, the first reactor to use thorium and uranium- 233 was built there. The Molten-Salt Reactor Experiment operated from 1964 to 1969. It was then abandoned for lack of funding.

A MSR can run continuously, without requiring breaks for « refueling ». Liquid, the fuel can be extracted and recycled continuously, somewhat like a pool water that is permanently filtered. Fission products can therefore be removed daily to be stored away from the reactor. As for actinides, plutonium and minor actinides, they remain in the core until they in turn undergo fission and are therefore completely « burned ».

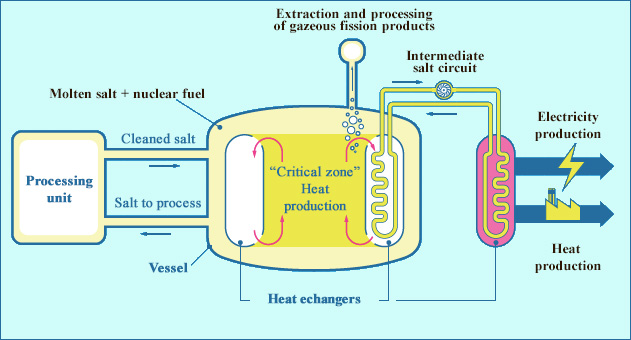

Operation principles of a molten salt reactor

Nuclear fuel is mixed with molten salts. In this liquid state it undergoes fission reactions under the effect of neutrons. On the right, heat exchangers allow the energy produced to be recovered. Gaseous fission products are continuously extracted. Other fission products are extracted from the molten salts in a reprocessing unit on the left. This extraction would probably not be carried in a continuous flow, but rather in the form of daily or weekly punctures.

© RGN

These reactors could operate at atmospheric pressure unlike today pressurized water or boiling water reactors. Then, they would then not require enclosures to contain these high pressures. They could be simpler to build, therefore cheaper.

In the event of a serious accident, the dispersions of radioactivity would be much smaller, since there would be no accumulation of radioactive products in the liquid, which are extracted continuously from the reactor vessel.

Molten salt reactors are often associated with a fuel of thorium and uranium-233. With such a mixed fuel, MSRs can be operated as breeder reacors for the whole spectrum of neutrons, slow neutrons and fast neutrons. To be started, these reactors require the addition of fissile plutonium-239.

Loaded with a thorium-uranium-233 fuel, MSRs could incinerate long-lived waste such as minor actinides which would be introduced into liquid salts. The actinide nuclei are big and fragile fragile. One way to destroy them is add extra neutrons by neutron captures until they explode by fission.

Current reactors do not facilitate multiple captures, since their fuels stay only 3-4 years in the reactor core. To effectively burn actinides (and plutonium), longer stays in the reactor are required. With a molten salt reactor, the minor actinides would stay long enough to be burned in the kind of soup that is a liquid fuel.

Oak Ridge National Laboratory video devoted to the small 8 MW Molten Salt Reactor which operated from 1965 to 1969 in this laboratory.

Since the years 2000s, molten salt reactors are considered, within the framework of the International Generation IV Forum, as one of the options for reactors of the future. Research is carried out in France by the CNRS in a Grenoble laboratory, in conjunction with the CEA (French nuclear Agency) and Framatome. Outside France, mainly China and the United States are funding research programs to develop this technique on an industrial scale, with China declaring that it wants to build an MSFR (Molten Salt Fast Reactor) by 2030.

Attractive at the design level because of their multiple advantages, including that of being able to use thorium as fuel, these reactors still remain at the level of principles. Many technical problems remain to be resolved. Technological obstacles have to be overcome in terms of materials, maintenance, complex and evolving chemistry. For example, an alloy must be found that can withstand for years corrosion of molten salts at a temperature of 600-700 ° C.

Many studies and tests will be necessary before the realization of a demonstrator. No construction of a prototype reactor is currently underway. It would also require a certification process which would not be simple, given the originality of the concept, and which no one has yet engaged

Other articles on the subject « Future Reactors »

Generation III Reactors

The reactors of tomorrow before those of after tomorrow Designed in the 1990s, third-generation r[...]

EPR Reactors

EPR: a third generation pressurized water reactor Third generation reactors are reactors intended[...]

The nuclear option ?

Energy challenge : meeting energy demands of the Future The emergence of huge future needs by de[...]

Generation IV

Towards a fourth generation of reactors To meet the formidable challenges of sustainable developm[...]