Evacuate the heat of fissions and radioactive decays

To ensure the safety of a reactor requires to ensure the cooling of the nuclear fuel, in other words the effective removal of heat that comes out. This requirement must be satisfied at all times: both during the running of the reactor and after its shutdown normal or accidental.

Two of the three major nuclear accidents that happened so far were due to a cooling failure. At Three Mile Island in 1978, the accident was limited to the loss of a reactor. At Fukushima in 2011, reactors were shut down when the tsunami drowned and put off the emergency electrical installations that were poorly shielded. Loss of a proper cooling was at the origin of the major releases of radioactive materials into the environment that occurred several days later.

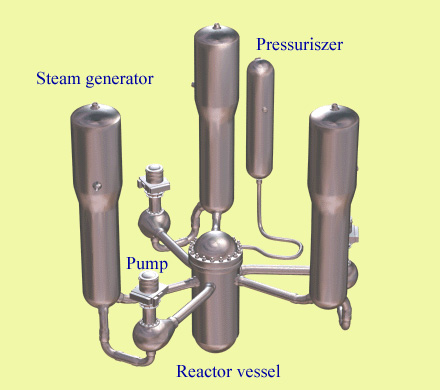

Primary loop in a PWR

The circulation of the primary water is provided by a group of pumps. A pressurizer, connected to the hot branch of one of the primary loop, maintains the water to the nominal pressure of 155 bars and limits the pressure variations when the reactor charge varies. It is essential to guarantee in all circumstances, thanks to emergency devices, the water circulation and heat dissipation through the steam generators..

© EDF

In operation, the heat generated by fissions occurring in the fuel rods of a PWR is evacuated by the primary water in contact with the fuel assemblies. Between the inlet and the outlet of the reactor vessel, the primary water temperature increases from roughly 280 to 320 ° C. Then it goes down to 280° C in the steam generators, where evacuated heat is used to vaporize the water of the secondary circuit to produce electricity. In the central region of the reactor core, where the rods generates the highest power, the cladding temperature reach 400 ° C while the temperature at the centre of the uranium pellets exceeds 1000 ° C. Short power variations of that results in brief temperature rises are evacuated through steam generators and various safety devices.

One can not afford any interruption of the heat evacuation, otherwise the temperature of the cladding and the fuel increases rapidly, causing breaks and even its fusion and a more or less complete melting of the fuel pellets. For all this to work well, it is necessary that the primary water is at the correct pressure, that it flows perfectly and that the heat is evacuated continuously. Steam generators there play a key role: the heat evacuation supposes a perfect transfer to the water from the secondary circuit.

The installation should ensure the cooling of the reactor pressure vessel (RPV) in case of rupture of one of the many water diversions of the primary circuit, but also in the case of a major break in a major pipe.

An other essential cooling is implemented after a normal or emergency shutdown of the reactor. The shutdown stops the fission reactions, but not the decays of radioactive atoms that continue to release an intense heat: Immediately after the shutdown this heat still represents around 5% of the reactor thermal power. Cooling is achieved differently, since the reactor no longer produces electricity. It requires an external source of cold water. This cold water should be injected into relevant heat exchangers.

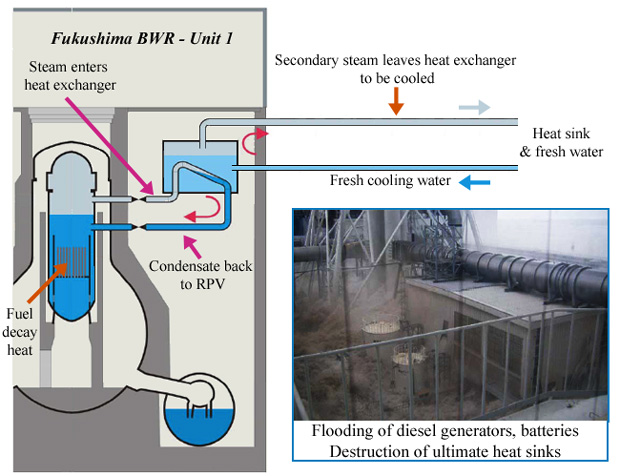

Cooling failure caused by the Fukushima tsunami

Fukushima boiling water reactors were safely shutdown after an earthquake. Before the tsunami arrival the decay heat in the reactors core were cooled following a standard process. In the case of the unit 1, steam coming from the reactor vessel went into an heat exchanger before returning to the core. The secondary water vaporized in the heat exchanger was replaced by fresh water injected from an external source. When the tsunmi flooded the diesel generators and electrical equipments allowing pumps and water injections, cooling in the reactor was interrupted, causing the accident…

© IN2P3 (Source AREVA)

Accidents like those of a major break in a main pipe provoke the immediate shutdown of the reactor, but as before one has to remove the residual still very important heat due to radioactive decays. A security system is designed for this parade: the « safety injection system » that includes devices in order to cover all possible situations.

Such devices differ in the pressure at which they are able to inject water into the primary circuit and by their flow. For instance a “high pressure safety system” is designed to inject water at a pressure greater than the nominal pressure (this device is intended to deal with a rather serious leak); A “low pressure safety system” intervenes when the pressure has fallen below a ten bars (or atmospheres) or in the case of a major water leak.

Other articles on the subject « Reactor Safety »

Confining Radioactivity

Three barriers … One major challenges of nuclear installations safety is to master the conf[...]

Reactor Shutdown

The embers of fission … When shutting down the reactor, whether for reloading the fuel or a[...]

Reactor maintenance

Provide the best safety for reactors during decades Nuclear reactors are designed to operate for [...]