BWR or Boiling Water Reactors

Boiling water reactors or BWR are in operation in the United States, Japan, Germany, Finland, Russia, Sweden, Switzerland and various other countries. For electricity generation, BWR comes second after pressurized water reactors (PWR), well before CANDU and RBMK reactors. It represents around a quarter of the worlwide number of reactors in operation today.

This brand of reactors, which use thermal neutron moderated by ordinary water, was designed in the United States. The construction of the boiling water reactor has long been the specialty of the General Electric manufacturer (GE). The first commercial unit was that of Humboldt Bay near Eureka in California. The electrical power of today BWR reactors is between 570-1300 MWe.

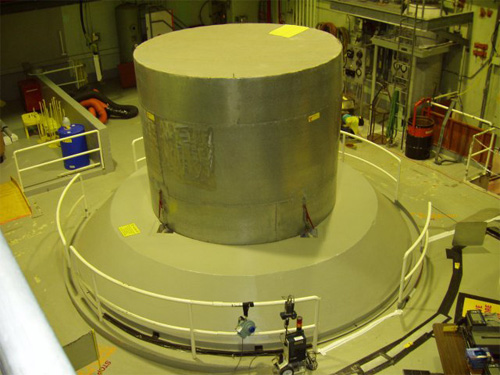

A precursor reactor: The Humboldt Bay BWR

The Humboldt Bay reactor, located near Eureka in northern California, was the precursor of boiling water reactors. Built by General Electric, it was in operation from 1963 to 1976. Its electric power was of 65 Megawatt (MWe). At that time, it was shut down to undergo transformations in order to prevent seismic risks. Then, after the 1978 Three Mile Island accident and because of the cost of the required transformations, the California electricity company PG& E decided to dismantle the reactor.

© NRC

These reactors owe their name to the fact that the heat generated by fissions turns the water that bathes the reactor core into steam that directly drives turbines which produce electricity. In a PWR on the contrary, the reactor core heats water, which does not boil being under high pressure. This hot water then exchanges heat with a lower pressure water which turns into steam to drives the turbines.

There is less containment barriers in BWRs between the radioactive fuel and the environment. The fuel cladding therefore needs to be particularly waterproof. The tightness of the cladding and the turbine circuits should be closely monitored. The steam extraction should be quickly isolated and stopped, if a tightness loss is detected implying the presence of fission products in the turbine part of the circuit.

The Fukushima reactors were BWRs. The less efficient containment of fission products has worsened the accident. For instance, extremely radioactive puddles were observed on March 25th, 2011 in the turbine hall

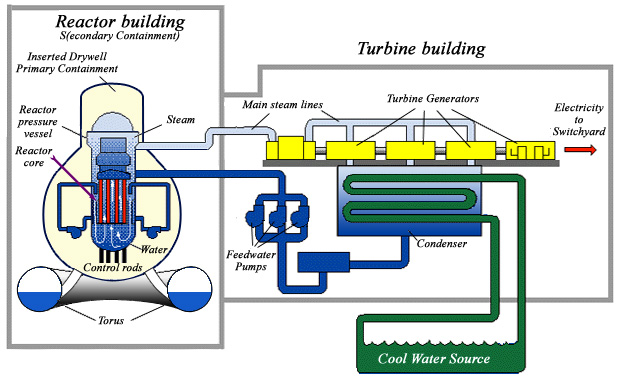

Layout of a boiling water reactor

Heat from fuel assemblies vaporises water flowing through the reactor pressure vessel into steam. The water-steam level in the vessel is measured continuously and contributes to the overall reactor control. The steam is separated from the water before going to the turbines and produce electricity, then, cooled and condensed by a circulating flow of cold water (sea, lake, river water). Condensed water recovered at low pressure by pumps, is re-injected and recycled into the reactor core.

© DR

The primary water management is more restrictive and complex than for a PWR, since the steam carries radioactiveity due to the strong irradiation of water. The turbine hall of a BWR is operating in a controlled area, but the main radionuclides formed being very short-lived (under 10 seconds) there is no real problem for maintenance. Primary water should be filtered and purified strictly before its return into the reactor vessel.

The steam temperature is around 300° C and the pressure between 70 and 80 atmospheres, about half that of the PWRs pressurized water. The thermodynamic efficiency of transforming heat into electricity, is close to 1/3, slightly above that of a PWR.

Control rods are inserted and moved from below the reactor vessel via a high hydraulic pressure system, a feature of BWRs. The insertion of neutron absorbers in the event of emergency stop, therefore does not rely on gravity.

A BWR peculiarity : a sudden increase in steam pressure causes condensation and increases the proportion of liquid water. This surplus of water, that fosters moderation of neutrons, favors fission reactions and increases the energy released. In order to fight the destabilizing effect of such « pressure transitories”, BWRs are equipped with a set of safety valves that vent the steam pressure excess, collect it after condensation in a « wet torus » located under the pressure vessel.

BWRs containment vessels are under an inert atmosphere in depression. This has the advantage of preventing the risk of fire. This helps also prevent hydrogen explosions in case of major accident, when hydrogen is produced by a zirconium cladding fire that decompose steam above 1000 ° C. Normally, containment vessels should also be equipped with hydrogen recombiners. This was not the case unfortunately of Fukushima BWRs in 2011.

BWRs with their unique loop require less instrumentation and are simpler than PWRs with their primary and secondary loops. Investment costs and construction times are lower, but the difference in the final cost of electricity is small. The core of a BWR is less compact than that of a PWR and bigger. It contains 4 times more fuel elements and requires more control rods, at equal power. Finally, disadvantages and advantages of the two types of reactors are balanced.

Other articles on the subject « Nuclear Reactors »

Reactor Families

A variety of designs : Natural uranium or enriched uranium as fuel There are several industrial t[...]

World nuclear reactors

A development that takes place today in Asia At the beginning of 2014 the number of reactors in o[...]

Generation I reactors

1950-1970: First generation of reactors (50 – 500 MWe) The first generation reactors were i[...]

RBMK reactors

Soviet-era reactors at Chernobyl Cold War and the Iron Curtain led after 1947 to the development [...]

Generation II Reactors

1970-2009: the rise of nuclear energy About 85% of electricity produced worldwide by nuclear powe[...]

PWR Reactors

The most widespread type of reactor … Pressurised water reactors (PWR) are by far the most [...]

PWR Operation

High pressure water to evacuate heat and slow down neutrons The reactor core is the source of ene[...]

Candu reactors

Canadian reactors using natural uranium and heavy water CANDU is a nuclear reactor brand develope[...]

Nuclear Propulsion

On-board reactors for submarines and aircraft carriers In addition to conventional land-based pow[...]