Past achievements and future improvements

Reprocessed tonnages

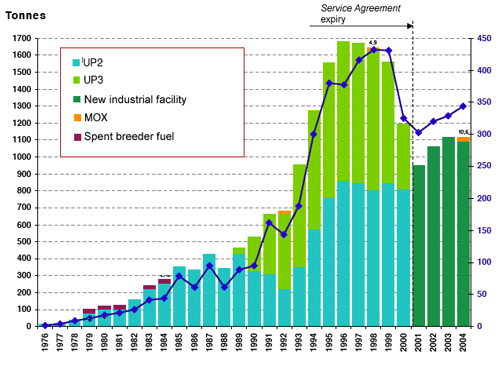

Since La Hague facility was commissioned in 1976, annual production has grown from a few tonnes to 1,100 tonnes of spent fuel processed in 2004. The decrease observed in 2000 was due to a reduction in the share of overseas customers. Note that small quantities of MOX were reprocessed during 3 campaigns in 1992, 1998 and 2004. The curve and scale (on the right) in terawatthours show the change in electric power generated using fuel processed in La Hague.

© AREVA

When the plant in La Hague was commissioned in 1976, its annual output amounted to a few tonnes of processed spent fuel. Production rose to a peak in 1997, and totalled 1,100 tonnes in 2004, giving an indicator of the progress accomplished. Fuel production for overseas customers declined in subsequent years. Germany finished reprocessing its waste in 2010. Japan also stopped sending its spent fuel to La Hague, having built its own plant in Rokashomura.

PUREX is a proven process that has benefitted from numerous technical improvements over the years. The uranium and plutonium recovery rate approaches 99.9%, due to the selectivity of the solvent used for the extraction process (tributyl phosphate). Uranium and plutonium recovery performance is excellent.

Processing spent MOX fuels, reputed to be difficult due to their higher radioactivity, became a reality in 2004. It is in principle possible to recycle plutonium a second time in MOX fuel, then in the reactor. This possibility is not envisaged for current PWR reactors, but may be for EPR reactors.

A reductio n of waste volumes

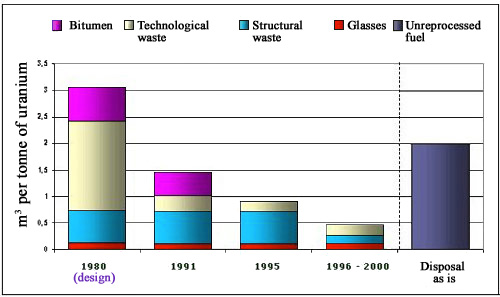

One of the benefits of reprocessing has been a six-fold reduction in waste volumes. Residual waste after reprocessing now takes up four times less space than non-reprocessed fuel. Although there has been little change in the volume of the most radioactive waste (HLW glass packages), the volume of technological waste from reprocessing operations and ILW-LL structural waste (cladding hulls and end-pieces) has decreased considerably. Bitumen is no longer used.

© AREVA

Reduced waste volumes and environmental releases

A major benefit is the reduction in waste volumes, despite an increase in the volume of spent fuel processed. Compacting solid waste (in particular, fuel-containing cladding fragments) considerably reduces the volume of intermediate-level (ILW-LL) waste. As this category of waste releases little heat, the reduction in volume will facilitate disposal.

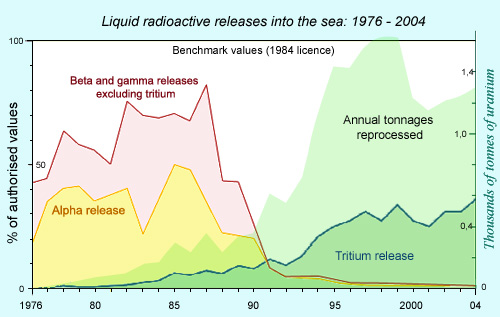

Reprocessing plants release small quantities of gaseous or liquid radioactive waste (in particular tritium) into seawater around La Hague. No solid releases are permitted. Gaseous and liquid releases must comply with statutory limits. Releases are monitored by independent European agencies. Despite increasing plant output, the quantities of such environmental releases (other than tritium) have fallen spectacularly as a result of the measures adopted. In 2004, releases were at around 1% of the authorised amounts.

Environmental release trends

The evolution of the three types of releases into the sea from La Hague plant, are shown together with the plant output (in tons reprocessed) since 1976. Releases are expressed as percentages of the authorised limits. These limits are particularly stringent for more toxic waste: 1.7 TBq per year for alpha emitters: 1,700 TBq/year for beta emitters other than tritium; 37,000 TBq/year for tritium. The chart cshows how releases of alpha and beta emitters have fallen dramatically despite the production ramp-up. Tritium releases, which are difficult to trap but not highly radiotoxic, broadly kept pace with production.

© AREVA

In application of laws passed in 1991 and 2006, research is conducted with the aim of decreasing the remaining residual releases:

– Technetium: This long-lived fission product limits performance of the uranium and plutonium extraction and separation process, as technetium tends to take the same route as uranium. The research conducted holds out the prospect of industrial solutions that would enable 99% of technetium to be recovered, compared with the current level of 90%.

– Iode-129: This very long-lived fission product (which has a radioactive half-life of 15 million years) is released during the shearing and dissolution operation. Not all of it is trapped, allowing a fraction to enter the environment. Iodine-129 is only slightly radioactive. Specific gas stripping and trapping would enable 99% of iodine to be recovered, compared with the current level of 90%.

– Tritium: The radiotoxicity of tritium is particularly low (2,600 times less than iodine-129) but no practical solutions for trapping it have been identified. Note that tritium is also produced naturally by cosmic radiation.

A proven, smooth-running industrial process like PUREX is difficult to change. The production of high-level waste in the form of glass package cannot be called into question. There are no short-term plans to implement the results of current research into more comprehensive separation of the radioelements present in this waste, such as minor actinides.

Learn more :

Area 1: Partitioning

Advanced partitioning

Advanced partitioning

Radioactive Toxicity

AREVA la Hague web site

Other articles on the subject « Fuel reprocessing »

Reprocessing operations

A multi-year sequence of operations Reception of the spent fuel assemblies is the first stage of [...]

Purex process

Purex – Industrialised spent fuel processing Fuel is processed at the LaHague facility using a hy[...]

Effluents and releases

Low and well-controlled environmental releases A small portion of the radioactive waste from nucl[...]

La Hague – Safety

Safety issues different to those faced by reactors The events of 11 September 2001 raised the spe[...]