Dry storage of vitrified waste

Interim storage of vitrified waste

Vitrified waste from reprocessing activities is stored in ventilated shafts located below the floor of this large hall at the la Hague plant. The shafts are located below the « manhole covers » visible in the photograph. Despite the very high radioactivity stored, the radioactivity emerging from the floor is low enough to enable technicians to access the hall floor, as demonstrated in the photo.

© PHILIPPE LESAGE /AREVA

Spent nuclear fuel assemblies are not the only materials removed from reactors that must be placed in interim storage. After reprocessing spent fuel to recover the uranium and plutonium contained in it, the highly radioactive waste produced by the reprocessing operation must be managed. This is the case in France, where a second type of interim storage is used for such materials: dry storage.

Reprocessing residues consisting of fission products and minor actinides have been vitrified and placed in containers. These vitrified waste containers inherit the radioactivity already present in the spent fuel, other than that emitted by plutonium. They were originally produced and stored in Marcoule, but are now stored in ventilated shafts at the plant in La Hague. Heat is removed by either natural or mechanical convection.

Before the vitrified waste packages are stored in this way, the fuel assemblies had already been stored in pools prior to processing. As the name « interim storage » suggests, this solution is in principle temporary. However, it is the current end point for high-level waste pending decisions regarding their final destination, which will almost certainly be disposal in a geological repository.

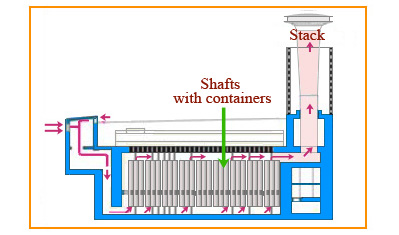

Cross-section of a vitrified waste storage building

This cross-section of the vitrified waste store in the Hague plant illustrates the principle of harnessing natural convection to cool vitrified waste packages located in shafts. As the stack creates an air draft, no mechanical ventilation system is required.

© Clefs CEA

At the La Hague plant, the shafts are located under the floor of a large hall featuring multiple « manhole covers », as the shaft cover plates have been aptly described by the Chairman of the national assessment commission (Commission Nationale d’Evaluation – CNE). The waste is located under the floor. Most of the radioactivity produced by reactors since the start of the French nuclear programme lies under this floor. Despite the « radioactive inferno » beneath their feet, the photograph shows operators going about their business without requiring too many obvious precautions. This shows that effective protection against even high-level radioactivity can be afforded by a good thickness of material able to absorb the most penetrating rays.

Vitrified waste from the earliest French reactor process – the natural uranium-graphite-gas (Uranium Naturel Graphite Gaz – UNGG) process, subsequently discontinued in favour of the current pressurised water (PWR) reactors – is stored at the Marcoule facility. The high-level waste from this process has been vitrified. Solutions containing fission products and minor actinides have calcined and embedded in a glass matrix by a processing line in the vitrification shop (Atelier de Vitrification de Marcoule – AVM) since 1978. Spent fuel processing at Marcoule ceased in 1997. The vitrified waste containers are stored in pits at the Marcoule site.

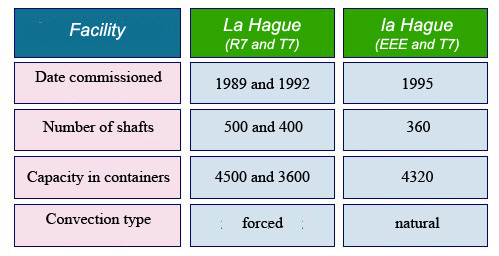

Vitrified waste interim storage facility specifications

The table contains information relating to vitrified waste interim storage facilities in La Hague. These facilities are cooled by natural or mechanical air circulation. The shafts are sealed and a partial vacuum created, and the air in them is treated and conditioned.

© IN2P3 (Source : RGN)

For how long will it be possible to continue using these interim storage facilities? This is one of the themes of current waste research. According to the national assessment commission (Commission Nationale d’Evaluation – CNE), « current industrial interim storage of high-level waste, as practiced in La Hague, appears to comply with all reasonable foreseeable requirements« . This practice may be extended for an indeterminate period – possibly 70 or 100 years – subject to construction of an additional wing at the La Hague facility.

NEXT : Spent fuel storage

Other articles on the subject « Waste management »

Waste management status

Repositories already in operation for low-level waste Compared with other types of waste, the mas[...]

Other storage facilities

Interim waste storage according to their nature and origin Spent fuel and vitrified waste from Pr[...]

Temporary storage

A temporary solution Interim storage is a temporary solution that plays a central role in the man[...]

Spent fuel storage

Interim storage in pools and then dry locations In all countries, spent fuel management begins wi[...]

Management outside France

Overview of waste management strategies outside France Management of the least radioactive waste [...]

LILW-SL waste repository

Disposal of low and intermediate-level short-lived waste Low and intermediate-level short-lived w[...]

VLLW repository

An operational repository for very low-level waste The second category of waste for which a repos[...]

High level waste transportation

Moving highly radioactive materials The 10% of transport movements that concern high-level radioa[...]

Transport safety

Measures to ensure safe transport Nuclear materials may be highly radioactive. The goal is to pre[...]

Transport-related incidents

Incidents but no accidents… Have radioactive material transport operations caused any accid[...]